Receipt of Goods

Receiving goods is a crucial part of the logistics process that ensures the quick and error-free preparation of goods for further processing. Proper procedures minimize the risk of errors and delays and ensure the smooth operation of warehouse activities. Below is an overview of the individual steps – the first two steps are client’s responsibility:

Step-by-Step Guide to Receipt of Goods

Stock advice and plan for receiving goods into the warehouse → client's responsibility

Preparation of goods before sending to the warehouse and their dispatch → client's responsibility

Inspection of received goods → warehouse's responsibility

Completed receipt → warehouse's responsibility

1) Stock Advice and Scheduling of Inbound Shipments

To ensure the smooth movement of your goods in the warehouse, it is essential to always create a stock advice before sending them. This applies to both newly arriving goods in packages and larger deliveries in the form of pallets.

For pallet deliveries, it may be also obligatory to reserve a time slot in the Time Slot Control system in some countries.

In the case of container transport, due to its complexity and size, coordination with customer service is required.

If you plan to send 6 or more pallets of goods to the Mailship portal, please let us know in advance. Contact customer support and check if we have the capacity to receive the shipment.

This procedure helps prevent delays and complications during delivery, ensures accurate record-keeping of goods, and contributes to the smooth flow of logistics operations. Adhering to these steps speeds up the processing of shipments and improves collaboration with the warehouse team.

Submitting Stock advice - Always

You can create stock advice directly in the Mailship portal, and the procedure for submitting it can be found here: Creating Stock Advice

Without a properly filled stock advice, goods cannot be stored, and the receiving time will be extended. If the stock advice is missing, customer support will contact you, and this service will be charged as an unannounced delivery.

Reserving a Time Slot - Container Transport

To ensure the smooth unloading of pallet and container shipments, in some of our countries it is necessary to reserve a time slot in the TimeSlot system. Your registration details have been sent to your email. If you need to retrieve them, please contact customer support.

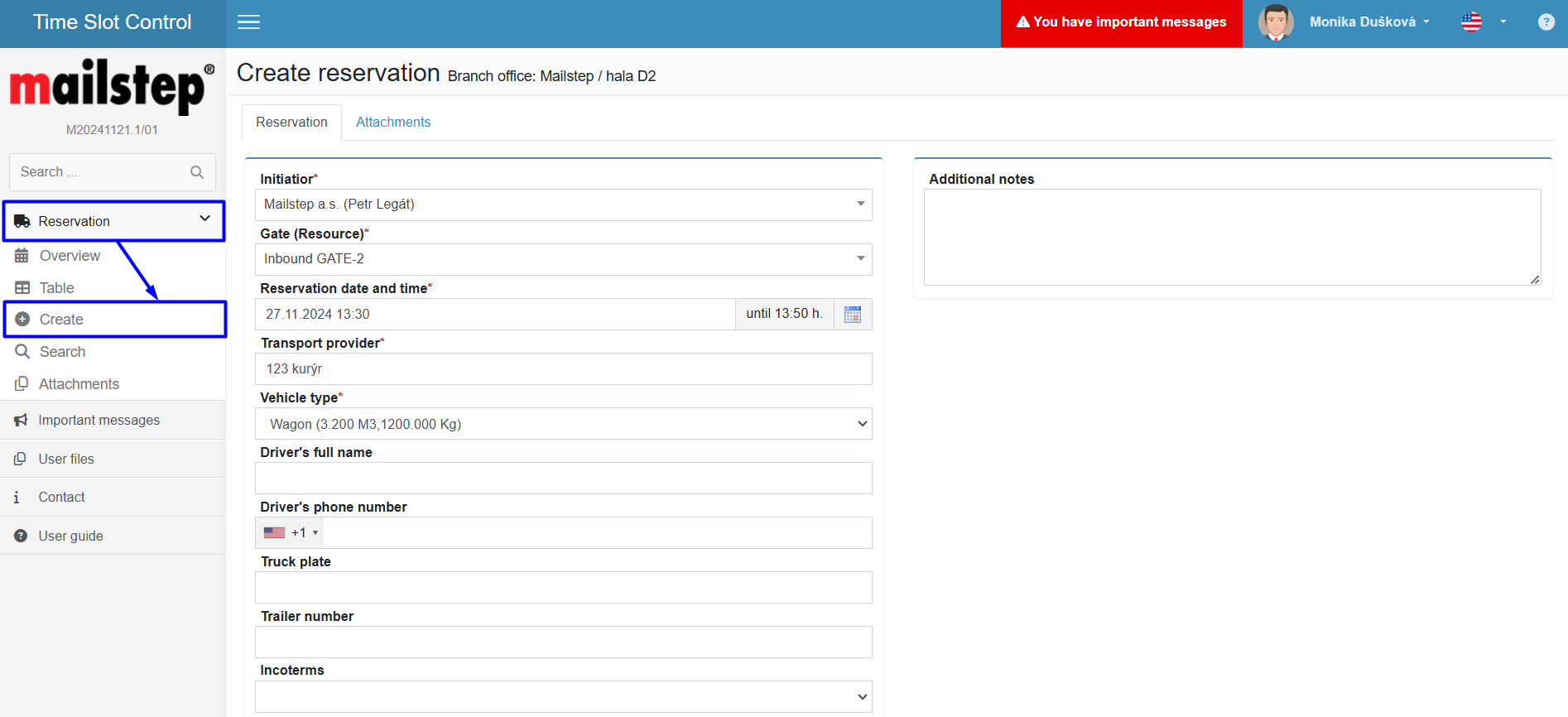

Log in to the Time Slot Control portal

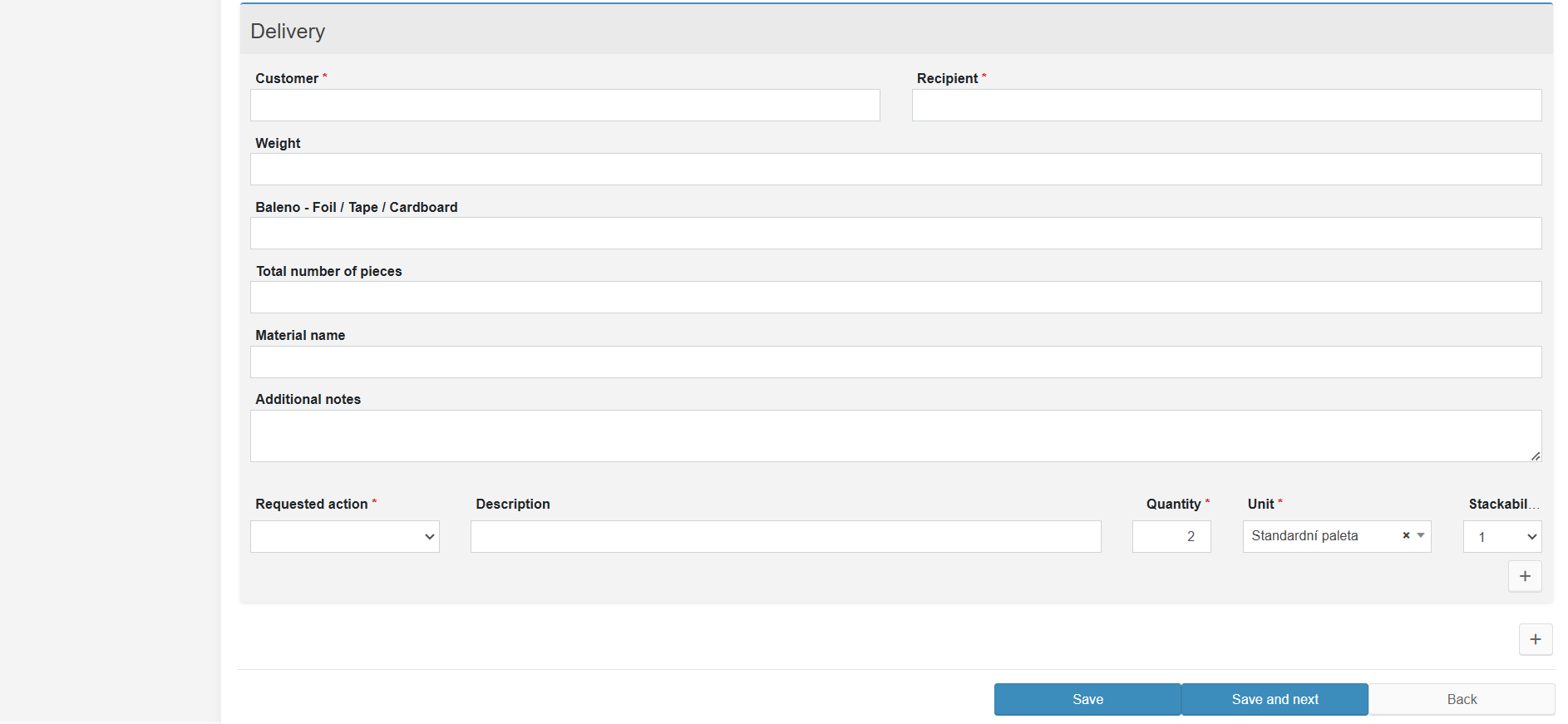

In the Reservation section → select New

Mandatory fields are marked with an asterisk

Fill in particularly the day and time of arrival

If the reservation is missing or the exact arrival time is not respected, unloading will not take priority.

2) Preparation of Goods Before Sending to the Warehouse

To ensure smooth receiving, it is necessary to ensure not only notifications of deliveries but also to prepare documentation and properly package and label the goods.

Correct product setup in Mailship

When creating a new stock item, make sure it is set up correctly. The most important part is the EAN/code, which warehouse workers use to identify the product with a scanner. If the physical barcode contains different data than what is in the system, it can cause complications and delays during the inbound process.

You can find more information on how to correctly create product cards: Creating a Product

Changes to already stocked products are not always possible – for example, editing LOT tracking. That’s why we recommend enabling the LOT tracking feature for all products with an expiration date or those linked to specific batches.

Documentation for Goods

A handover protocol, must be attached to the goods. This document should contain key information such as: the number and type of transport units, delivery address (Mailstep/Mailship - the name of your e-shop), and the name of the sender.

Do not forget to include the stock advice number and the reservation number from Timeslot, which is essential for accurate management of the pallet account between you and Mailstep/Mailship.

Labeling and Packaging of Goods

Goods should be packaged appropriately to prevent damage during transport. In the case of pallet or container shipping, proper packaging on pallets or in containers must be ensured.

Each item must have its own EAN code to be stored.

a) Parcel Shipping:

Pack the goods in boxes and ensure that each box has a unique shipping label.

The shipping label must be clearly visible, and any original labels must be removed or defaced.

Do not place the shipping label on the seam of the box, where it could be damaged when opening.

The label should contain information:

Place and name of the sender

Delivery location (Mailstep/Mailship - the name of your e-shop)

Package number out of the total (e.g., 2/5)

Always specify as the recipient not only the organization Mailstep/Mailship but mainly the name of your e-shop. This will prevent delays in receiving the shipment that could arise from searching for its owner.

b) Pallet Shipping:

Before unloading, it is necessary to check the shipping documentation and visually inspect the condition of the pallets.

Pallets are unloaded using a forklift.

After unloading, a visual inspection of the delivery is performed, as well as checking if the number of pallets or packages matches.

c) Container Shipping:

Contact customer service at least 3 working days before the arrival of the container.

The notification of planned delivery should include the client's/e-shop's name, container number and volume, type of packaging (pallets or loose), and the number of cartons.

3) Arrival of Goods and Their Inspection

The warehouse worker at the receiving area first checks the received goods against the delivery documentation, verifying the type and quantity of goods. Individual items are counted upon receipt. After the inspection is completed, the goods are handed over for storage.

In the case of discrepancies in the goods (quality/quantity of transport units) with the handover protocol, the customer service department will be informed of the situation.

You can find out how the processing of stock advice in the Mailship portal looks here: Stock Advice Processing Workflow

Discrepancies and Exceptions During Inbound

What situations may arise during receipt and how to resolve them? These adjustments relate to discrepancies between the stock advice and the actual received goods, which require corrections in the system and the recording of unannounced items.

Quantity Over Stock Advice | If more goods arrive than stated in the stock advice, the excess goods will be recorded and communicated to customer service. |

Item Not in Stock Advice | Goods not listed in the stock advice will not be accepted and will be recorded and communicated to customer service. |

EAN Code Discrepancy | In the case of a discrepancy between the EAN code in the stock advice and on the goods, receipt will be halted, and the situation will require manual inspection. |

Missing EAN Code | If goods arrive without an EAN code, customer support will contact you and arrange the next steps for labeling the goods. If the goods have an EAN code, but some pieces do not have it or the code is unreadable, we will ensure the reprinting of EAN codes. This service is charged according to the price list as "EAN label." If you know that the goods will arrive without EAN codes and you want us to label them with our own stickers, please include this information in the stock advice and send us identification instructions for the products along with the correct EAN codes in advance. |

Wrong or Damaged Goods | In the case of item mix-up or damaged goods, the situation will be recorded and dealt with by customer service. |

Unannounced Delivery | If the stock advice is missing, customer support will contact you, and this service will be charged as an unannounced delivery. |

4) Completed Receipt

After successful inspection and counting, the goods are stored in the designated location, and the receipt status is updated in the system. This completes the receipt process, and the goods are ready for further processing or dispatch.

In the Mailship portal, stock advices during receipt can have the following statuses:

Finished – All items have been successfully received and stored.

Partially finished – Some items were missing upon receipt. This status is final from the warehouse's side; further inspection and possible closing of the stock advice to the status "Closed" is on your side.

Details on processing inbound can be found here: Stock Advice Processing Workflow

Additional Services During Goods Receipt

When receiving goods at Mailship, you can use several additional services:

LOT Evidence – Ensures tracking of batches and expiration dates, suitable for products with a limited shelf life, such as food or cosmetics.

Additional Work on Receiving – Option for customized adjustments to goods, such as label removal, shrink-wrapping, or bubble wrapping.

Qualitative Receiving – Detailed inspection of goods upon receipt to reveal any defects that may facilitate the resolution of complaints.

Language Labeling for Products (Localization) – For API clients who need to ensure product labels according to the country of delivery.

How to Activate Additional Services

You can activate these services on the product card, except for language checking, which is only available via API. Detailed information on services and their activation can be found here: Services and Functions for Products